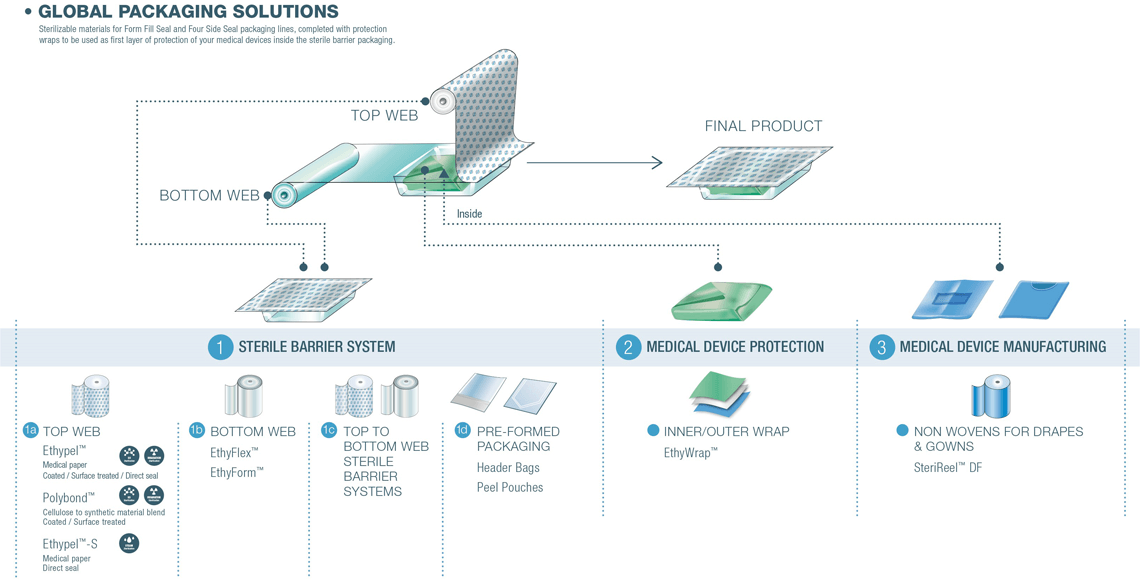

Our global offer

Expertise and Innovative Solutions for Infection Prevention

To best meet the market needs, STERIMED has developed product lines dedicated to different manufacturing and sterilization process types.

|

Maintaining sterility for 5 years minimum |

FOR:

- Packaging of syringes, catheters, gauzes, drapes, gowns, and many more

- Blister manufacturing

- Coating activities

TECHNICAL CHARACTERISTICS:

- Paper, Film, Reinforced materials

- Coating, Printing, Slitting

- 55 gsm to 117 gsm (34 to 72 lbs.)

- Conforms to EN ISO 11607-1: 2020, EN868-6: 2017, EN868-7: 2017

SEMINARS & TRAINING:

Pack Design Day :

www.packdesignday.com

Read more about Ethypel and Polybond solutions

|

Maintaining sterility for 180 days minimum |

|

FOR:

- Manufacturing pouches and tubing for sterilization in patient care units

TECHNICAL CHARACTERISTICS:

- Paper and Reinforced materials

- Printing, Slitting

- 60 gsm to 112 gsm (37 to 69 lbs.)

- Conforms to EN ISO 11607-1:2020, EN868-3: 2017

SEMINARS & TRAINING:

Hospital Pouch Partnership Program:

www.patient-safety-forum.com

Read more about propypel solutions

|

Maintaining sterility for 90 to 180 days minimum |

FOR:

- Distributors to hospitals

- Healthcare professionals

TECHNICAL CHARACTERISTICS:

- Crepe paper, Reinforced and Non-woven materials from 52 to 78 gsm (32 to 48 lbs.)

- SMS from 40 to 70 gsm (25 to 43 lbs.)

- Filters, Tray liners

- Conforms to EN ISO 11607-1: 2020, EN868-2: 2017

SEMINARS & TRAINING:

Patient Safety Forum :

www.patient-safety-forum.com

Download Sterisheet mobile app at: